Estimated reading time: 11 1/2 mins

Picture this: you’ve got a booming business, but your inventory is becoming as tangled as a bowl of spaghetti. You’re thinking about investing in an inventory management system, but you don’t want to make mistakes that will be expensive and just make the situation worse.

Well, you know what they say: the key to success is preparation. And when it comes to your ecommerce business, one area where preparation truly pays off is inventory management software implementation.

Why Bother with Inventory Management Anyway?

Alright, let’s lay the groundwork. Inventory management isn’t just about shuffling goods around; it’s the secret sauce that keeps your ecommerce engine running smoothly.

But there’s a twist.

Implementing the RIGHT Inventory Management System (IMS) for your needs is the true hero here. It’s like giving your business a turbo boost, and we’re here to help you avoid the epic fails that many stumble into during this process.

Enter the 10 Inventory Management Mistakes to Avoid During IMS Implementation

1. Insufficient Research and Planning

Benjamin Franklin once said: “If you fail to plan, you plan to fail.”

Choosing an IMS without thinking about how it’ll fit into your business’s daily operations is like wearing flip-flops in a snowstorm – total disaster.

Skipping the all-important strategic brainstorming is the equivalent of setting out on a trip without a compass. You will end up lost, trying to juggle inefficiencies on top of your already complex inventory, surrounded by confusion, delays, and unexpected hiccups.

Here’s a real-world scenario for you: You’re running an ecommerce store that sells artisanal, handcrafted candles. You’re thinking of implementing an IMS to keep track of your fragrant wares.

But hold up!

Before you click “implement,” think about how the tool will actually fit into your day-to-day candle-making activities. Ask yourself some questions:

- Will it help you track the different scents, sizes, and materials efficiently?

- Will it seamlessly integrate with your order processing system?

- Will it help you get your orders out on time?

Without proper planning, you might end up with a system that’s expensive, inaccurate, and wildly unhelpful.

Also, make sure you don’t get dazzled by all the fancy features available. Going for a tool with more bells and whistles than you actually need can turn the implementation process into a nightmare. Instead, opt for a solution that’s tailored to your specific requirements and workflows. It’s like choosing the perfect size of shoe – no pinched toes, no blisters, just smooth sailing.

We suggest taking the time to define your requirements, objectives, and the scope you want the tool to cover. Know exactly what you want before you dive in. After all, you’re investing a LOT of time, effort, and money to get this tool up and going. Don’t waste all that by not doing the all-important work of planning before you start.

2. Poor Data Quality

You’ve heard of “garbage in, garbage out,” right? Well, this golden rule isn’t exclusive to coding – it’s the law of the IMS land, too.

Think about it: implementing a new IMS on top of inaccurate or incomplete data will only get you incorrect inventory counts, ordering mishaps, and an assortment of other problems.

So, what’s the plan? Don’t just glance at your old data and hope for the best.

Perform a full-on inventory count just before you go live. It’s like practicing your lines before going on stage for the big show!

Also, you want to make doubly and triply sure that your data is clean BEFORE you put it into the new system. Here are some key steps involved in scrubbing old inventory data:

- Clean the Data Up: Remove duplicate records, correct inaccurate entries, and eliminate inconsistencies in the data.

- Validate the Data: Ensure the data adheres to predefined rules and constraints. For example, validate that quantities are numerical and positive, product codes follow the correct format, and other relevant fields are properly formatted.

- Standardize the Data: Format data uniformly, converting units and dates to a standardized format.

- Transform the Data to Fit: Adjust data to match the new system’s structure, reformatting fields and aligning attributes.

- Make Sure the Data is Relevant: Review and remove outdated, irrelevant, or redundant data to streamline the new system’s effectiveness.

- Enrich the Data: If possible, enhance the existing data with additional information that might be useful in the new system. This could include adding more detailed descriptions, images, or other relevant attributes.

3. Neglecting Scalability

Your ecommerce business isn’t stagnant – it’s a dynamic, ever-evolving entity. Neglecting to consider this growth when picking an IMS is like buying a cute puppy without realizing it’ll turn into a full-grown dog. It’s cute now, but will it still fit your lifestyle when it’s bigger?

Similarly, if your chosen tool can’t handle your expanding inventory needs, you’re in for trouble.

Picture this: your business is booming, orders are pouring in, and suddenly your IMS throws up its hands in defeat. It’s like your car stalling on the highway during rush hour – frustrating and potentially disastrous. You might outgrow your tool faster than a kid outgrows their sneakers, leaving you with two choices: either stick with a tool that’s too small or embark on a costly migration to a new one.

So, here’s the smart move: when choosing an IMS, think long-term. Opt for a tool that can flex its muscles as your business scales up. Scalability isn’t just a bonus; it’s the secret sauce to future-proofing your inventory management.

Scale up, my friend, or risk getting squished by your own success.

4. Failure to Involve Key Stakeholders

Ever planned a surprise party without the guest of honor? Yeah, it doesn’t work. Not involving key players in IMS implementation leaves gaps and confusion. Get your A-team on board for a smoother ride.

Don’t make the mistake of getting all set to roll out your new IMS, only to realize you’ve left out the very people who’ll be using it day in and day out. Without input from the end-users, you might end up with a tool that’s as appealing as a party without music.

Now, imagine you’re planning that epic bash. Would you keep the details to yourself and hope everyone miraculously shows up and enjoys it? Probably not. Similarly, not involving ALL key people – from different departments – in the IMS selection and implementation process is like orchestrating a silent party. No one’s on the same page, and chaos reigns.

Instead of sidelining key players, involve them from the get-go. Their insights can guide the IMS in the right direction, ensuring it’s user-friendly, efficient, and tailored to everyone’s needs.

So, here’s the savvy move: gather your key stakeholders around the table. Engage end-users, listen to their needs, and gather input from different perspectives. It’s a surefire way to make sure everyone’s on board and happy with the tool.

Think of it as designing a party where everyone leaves with a smile on their face.

5. Not Establishing Clear Processes

Introducing a new IMS without defining clear inventory management processes is like throwing a bunch of ingredients into a pot and hoping for a gourmet meal. You will probably end up with a tasteless mess. Your team might interpret tasks differently, data might go haywire, and chaos ensues. It’s like a culinary disaster that’s tough to swallow.

Now, imagine you’re baking a cake. Without a recipe, you’re winging it. But with clear steps and measurements, you’re on your way to a delectable treat.

Similarly, define standard operating procedures for your IMS – the recipe for success. Set guidelines and clear processes for how the tool should be used, from data entry to order fulfillment. It’s like giving your team a roadmap to efficient inventory management.

6. Ignoring Integration: Putting a Square Peg in a Round Hole

Picture this unpleasant scenario: your IMS lives on one island, your accounting software on another, and your sales platform is chilling on a third. Like castaways, these systems don’t talk to each other. Data ends up stranded, isolated in its own little silo.

If your inventory data isn’t in sync, you’re doubling up on efforts, wasting time, and making decisions based on incomplete information. Efficiency? It’s a no-show.

So, what’s the remedy? Integration, my friend.

Instead of those isolated islands, think of your systems as a harmonious orchestra. When the violins (IMS), trumpets (accounting), and drums (sales platforms) play in sync, you get a beautiful symphony of data accuracy and streamlined operations.

When implementing an IMS, make sure it can work seamlessly with your existing tools. Don’t skip this crucial step. Ensure your IMS can exchange data effortlessly, eliminating duplication and data silos.

Remember, integration isn’t just a nice-to-have; it’s the key to unlocking operational efficiency and success.

7. Lack of Thorough Testing

Ever bought a supposedly foolproof gadget only to discover it glitches like a broken record? Inadequate testing during IMS implementation is like that – a recipe for bugs, disruptions, and a headache-inducing tech dance.

Think of your IMS as a spaceship – before liftoff, you want to be sure it won’t crash and burn.

What’s the smart move? Thoroughly test your IMS before the big reveal. Put it through its paces in different scenarios. Ensure every button, function, and integration point works seamlessly. Think of it as a pre-flight checklist for your tech adventure.

But wait, there’s more. Don’t just test the IMS in isolation; make sure it can shake hands with your existing systems. Test data flow between systems – from sales to accounting – to ensure everything syncs perfectly.

Data needs to flow seamlessly between systems, so test, test, and test some more before going live.

8. Insufficient Staff Training

Picture this scenario: your employees are faced with a new tool that’s supposed to streamline their tasks, but they’re as lost as a sock in the laundry. Frustration sets in, mistakes multiply, and before you know it, productivity takes a nosedive. It’s like a comedy of errors, but not the funny kind.

So, what’s the antidote? It’s all about the training. Provide thorough training sessions to ensure your team understands the ins and outs of the IMS.

This may strike terror into your heart, since you’re probably as inexperienced with this tool as your team is. But that is the benefit of working with a partner who IS experienced, and can both implement the tool and train your team how to use it. That is the definition of a win-win!

Instead of throwing your team into the IMS deep end, equip them with the right knowledge and skills to navigate the system with ease. When they know what to do and how to do it, the IMS journey becomes an exciting adventure instead of a confusing maze.

9. Inadequate Expertise for Self-Implementation

Now, picture this: you’re all geared up to implement your shiny new inventory management platform, but there’s a problem – your team lacks the expertise. Without the right know-how, your IMS journey might become a rollercoaster of confusion, mistakes, and unforeseen obstacles.

So, what’s the solution? Call in the pros. Enlist experts who’ve aced the IMS game before. It’s like hiring a seasoned pilot to ensure your flight is smooth and safe. These experts can analyze your business needs, customize the tool, and guide you through the implementation process with finesse.

Here’s a tip: when choosing an IMS implementation team, think of them as your navigation crew. They’ll steer your ship through uncharted waters, avoiding hidden rocks and whirlpools. Their expertise is your secret weapon against the chaos that can come with self-implementation.

10. Missing On-Site Walkthrough Before Implementation

You’re almost there. You’ve thought about all these things and you’re ready to dive into IMS implementation, but oops – you didn’t mention some crucial details to your implementer.

An on-site walkthrough with a rep from the IMS or your implementation team before implementing an inventory management system before the implementation starts can prevent this.

Here’s a real-world scenario: your business is like a bustling city, and your IMS is the new road map. But if your mapmaker hasn’t walked the streets, they might miss key intersections or one-way alleys.

Never start building without knowing the lay of the land. Instead of relying solely on descriptions, it’s crucial to get your IMS team on-site for a thorough walkthrough. They’ll get a firsthand feel for your warehouse operations, notice the unique challenges, understand your workflow, and spot the places where your business might experience inventory management challenges.

It’s like having your party planner take a sneak peek to ensure every detail is perfect before the guests arrive. Make sure your IMS team knows every inch of your operation.

Benefits of Proper Inventory Management Software Implementation

Now, you might be thinking, “Alright, LedgerGurus, you’ve warned us about the pitfalls. But what’s the silver lining?” Fear not, we’re getting to that:

Streamlined Operational Workflows

Like a well-oiled machine, your business will hum along with smoothly integrated inventory management processes.

Accurate Inventory Data for Informed Decision-Making

No more shooting in the dark – your decisions will be backed by rock-solid data.

- Scalability to Meet Growing Demands

Your business will be a chameleon, adapting effortlessly to market changes and growth.

- Efficient and Error-Reduced Processes

Errors and inefficient processes? Nah, they’re old news. Your streamlined IMS will kick them to the curb.

- Improved Staff Productivity and Morale

Happy employees, higher productivity. It’s a win-win.

- Seamless Integration with Other Systems

Your IMS will be the ultimate team player, integrating seamlessly with your existing tools.

- Enhanced Customer Satisfaction Due to Accurate Stock Availability

Say goodbye to customer disappointments due to out-of-stock items, and the resulting loss of sales.

- Data-Driven Insights for Strategic Planning

You’ll be making moves for business growth based on data, not gut feelings.

For more information, read The Top 10 Benefits of an Inventory Management Software.

IMS Tools We Use & Recommend

There are several tools that we are very familiar with and can help you get started on. Each has different characteristics, and we can help you choose between them to get the one that is right for your business.

The tools we recommend are:

For more information, read 5 Tips on Choosing the Best Inventory Management Software for Your eCommerce Business.

Summary for Avoiding Inventory Management Mistakes

Phew! We’ve covered quite the ground, haven’t we? Remember, avoiding inventory management mistakes allows you to glide to success instead of crashing and burning. Proper implementation is dependent having all the right ingredients, and this will make all the difference.

So, before you dive headfirst into an IMS, take a step back. Plan, involve the right peeps, test everything, and make sure you’re using an implementation partner. LedgerGurus is a great choice because we’ve got so much experience and can help guide you painlessly through the process.

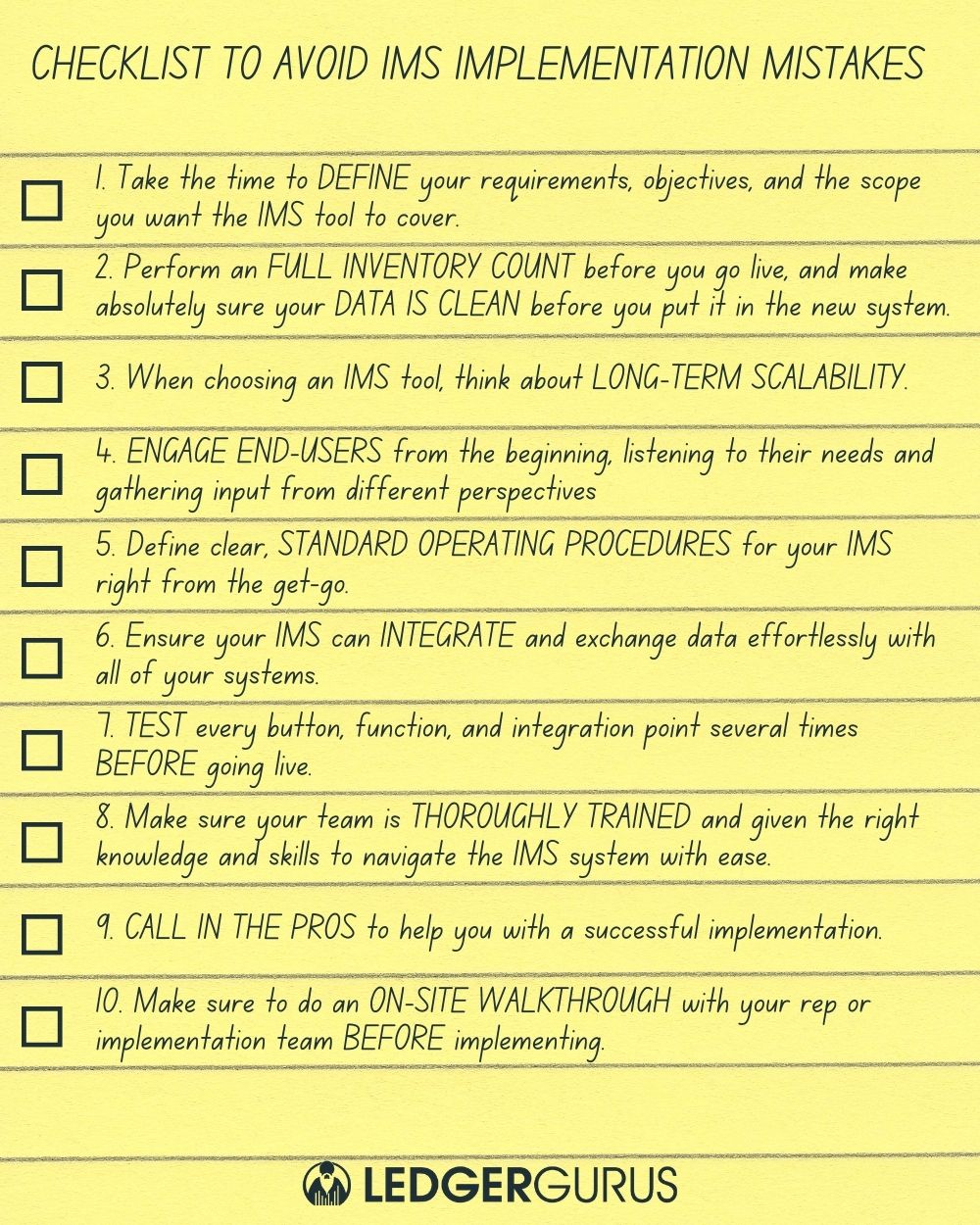

For a checklist of what to expect as we implement your IMS tool, download our Inventory Management System Implementation Checklist.